Description

Description :

EGYPSOL EMULSICUT 100 WS is a semi-synthetic, bio-stable, macro emulsion type extreme pressure water soluble cutting fluid. It forms milky to semi-translucent emulsions depending upon the quality of water used for emulsion formation. The solution formed is homogenous and does not break even during prolonged usage or shut downs.

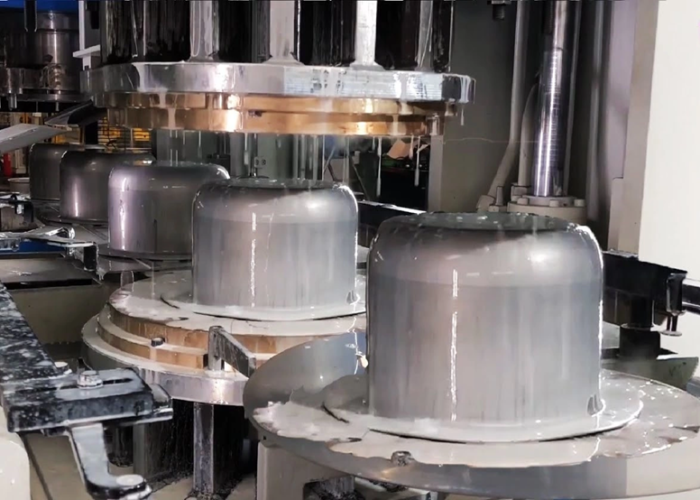

EGYPSOL EMULSICUT 100 WS is a low oil content Medium-EP type product whose emulsions are suitable for a operations on a wide range of ferrous alloys including high tensile steel and other difficult to machine alloys. These emulsions are also suitable for Aluminium alloys and yellow metal alloys.

Application :

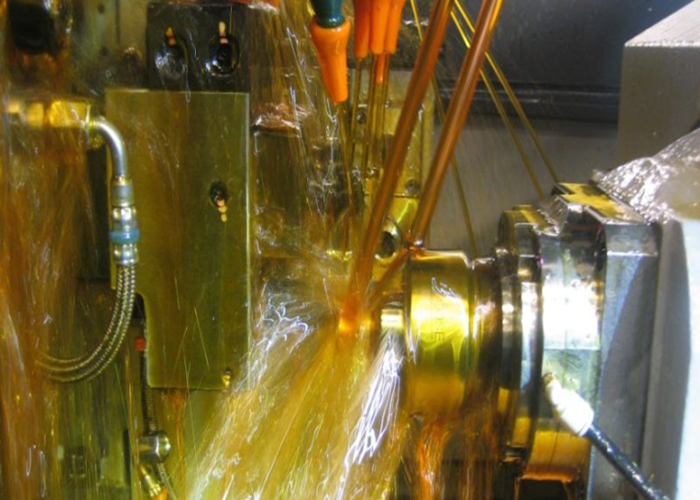

EGYPSOL EMULSICUT 100 WS is recommended for general purpose machining operations like sawing, milling drilling and other chip forming operations, general purpose surface, cylindrical and centreless grinding operations. Emulsicut 100WS gives excellent oil life, many times more than the conventional soluble cutting oils and also provides extended tool life and finish in general machining and grinding operations. These oils are also found to be very good in difficult operations or materials.

Recommended dilution rates for various operations are as under

- General machining: 5-7%

- Grinding: 3-5%

- Difficult Operations or Materials: 7-10%

Specifications :

This is a propriety formulation of EGYPSOL Petrochem

Reviews

There are no reviews yet.